Some Of Sheroz Earthworks

Some Of Sheroz Earthworks

Blog Article

The Single Strategy To Use For Sheroz Earthworks

Table of ContentsThe 7-Second Trick For Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.What Does Sheroz Earthworks Do?Things about Sheroz EarthworksWhat Does Sheroz Earthworks Mean?

For any type of earthwork specialist, it is vital to perform deal with high quality, accuracy, and on time. Utilizing machine control in work machines allows optimizing the different phases in the earthwork process, from preparing to the upkeep phase - topcon laser level. The device control system assists the machine driver in achieving the target airplane promptly and conveniently

The maker control system overviews the operator with centimeter precision. Remote support saves time and money, as it decreases downtime in jobsites.

The Best Strategy To Use For Sheroz Earthworks

Added training and directions are always offered over remote support when needed. The earthmoving sector has actually used our field-proven services given that the early 1990s. Our system's components are meticulously developed to withstand the harsh conditions of building websites. Comparison of the exact same task executed utilizing equipment control versus the typical approach exposes that, generally, the typical method requires 50% more time to complete the exact same task as the technology-assisted technique. https://www.bark.com/en/au/company/sheroz-earthworks/370va/.

Go into the Xsite equipment control system; it's here to provide you with a considerable advantage when working with earthmoving equipment. Discover exactly how Xsite Maker Control can boost your efficiency and make certain work safety and security! Xsite Maker Control systems can be installed to any excavator from mini excavators to big mining excavators.

How does maker control job? In 2D systems, the equipment is equipped with calibrated disposition sensors. These sensing units are installed on the pre-determined components of the device in excavators the sensor are normally installed to the framework, boom (or booms), digger arm and to the fast coupler - trimble gps. By utilizing the data obtained from these sensors the system can compute the specific position of the excavators bucket idea in relevance to a reference factor.

The system is extremely simple to find out the basics can be instructed in under one hour of training. Just how does the remote support work? A wireless internet connection makes it feasible to establish a remote link in between the device control system and the solution.

Sheroz Earthworks Fundamentals Explained

Xsite Device Control systems support open standard data layouts, making it possible for smooth details circulation from one system to one more. Depending on your selection of system (with or without placing, i.e., 2D or 3D), your maker is geared up with inclination sensing units, a controller device, and a display/operating panel.

Many hardware and software program services exist to help establish a device's existing position on the planet and compare it with a preferred style surfaceand building drivers Read Full Report can do even more to take advantage of the advantages. Machine control is using different placing sensing units and a screen to offer the operator with a recommendation in between the position of the container or blade and the target grade.

Depending upon the arrangement, machine control systems can supply the operator with an easy aesthetic guide to bucket or blade setting, or can instantly relocate the blade to quality by speaking with the equipment's hydraulics - https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks. There are equipment control systems offered for nearly any machine: graders, dozers, excavators, soil and asphalt compactors, scrapes, leaners, grating makers, and pavers

Sheroz Earthworks Can Be Fun For Everyone

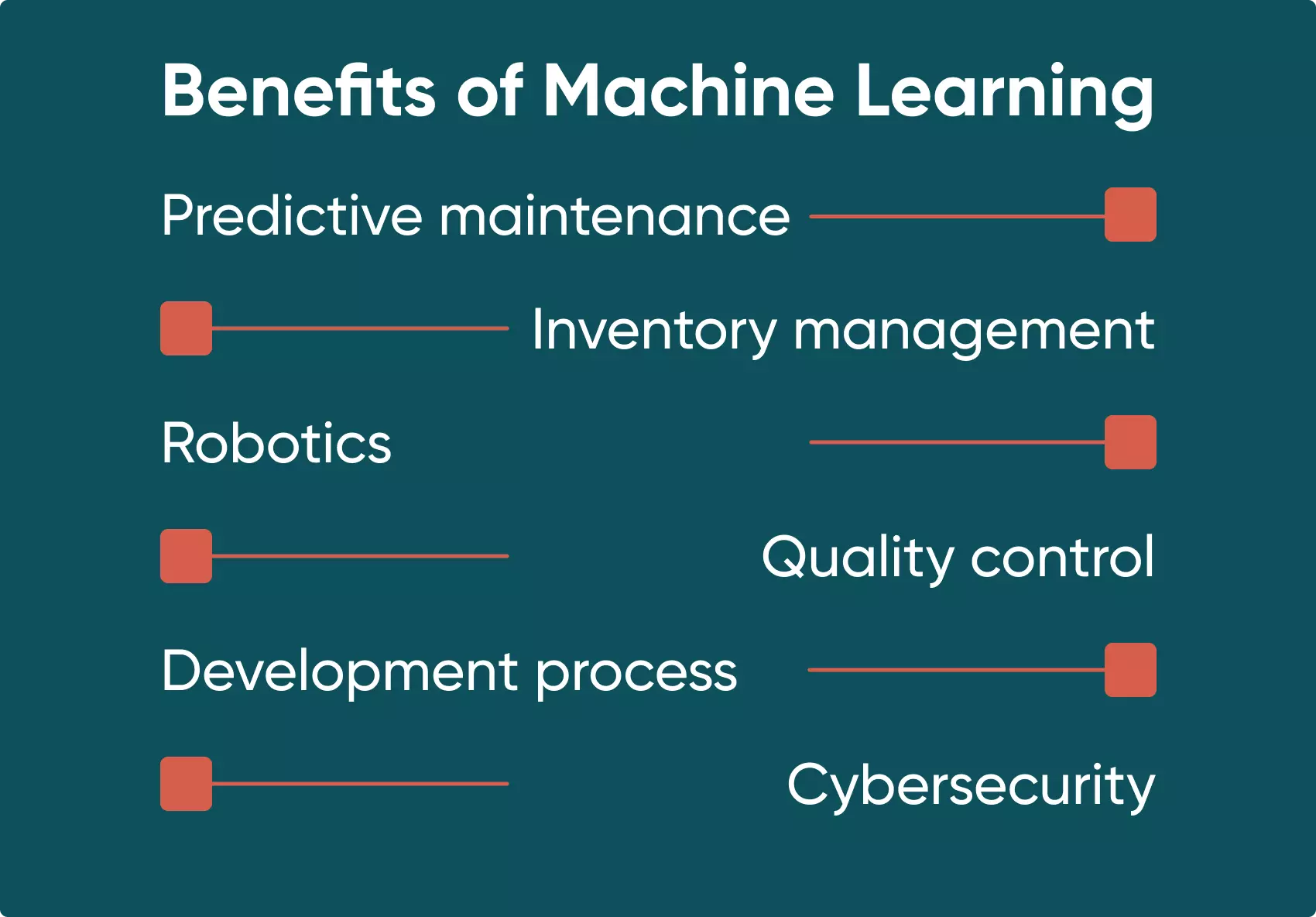

Maker control can likewise assist increase efficiency and minimize total expenses. Construction equipment without machine control will certainly end up being a thing of the past and the benefits acquired from it will be countless.

Trimble maker control systems offer a myriad of advantages to anybody who uses earthwork equipment and, at EarthCalc, we can provide you with 3D declare your equipment control-enable equipment. Uncertain if machine control is worth the cost? Think about the following factors why you need to consider this option.

Utilizing general practitioner lined up with your 3D layout files, these systems virtually guarantee that you will eliminate or position the appropriate amount of product at the building and construction site. On the majority of construction websites, rework is a common and frustrating reality, but with Trimble machine control, you can eliminate the demand for rework.

The 25-Second Trick For Sheroz Earthworks

Frequently, with Trimble equipment control, you can get rid of excess tools at a certain work website. A job that may have required the usage of three or 4 items of digging deep into devices currently might require only 2 items of tools to complete the very same job in much less time. This allows you to move your equipment to one more task website and take care of several work at once.

Report this page